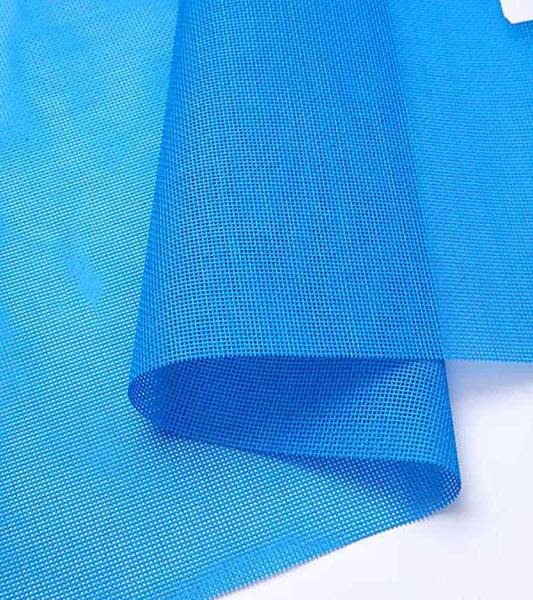

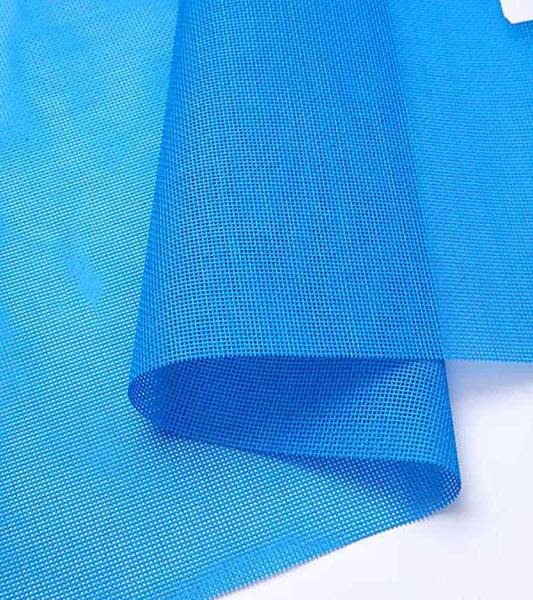

Typically made from polyester or nylon, mesh fabric is a breathable material that has a wide range of applications. Mesh fabrics are used in the medical, food, wastewater, and hygiene industries. It can also be used in the transportation, pharmaceutical, and apparel industries.

Mesh fabric is made by spinning synthetic fibers into woven fabric. The fibers are then combined with acids to create a net-like fabric. The end result is a breathable material that is strong and flexible. A variety of properties are engineered into the structure of the mesh, such as crocking values, which means that dyes won't rub off.

Using a

mesh fabric is easy. It can be sewn or cut, but it is important to handle the fabric with care. A mesh fabric can be cut with a rotary cutter or scissors. It is best to press the fabric before cutting, which will prevent puckering. Make sure to use a sharp blade for your cutting machine. The fabric should be cut in a cool setting to prevent overheating. It is also best to use a ballpoint needle. A ballpoint needle is small and has rounded points that won't cut the yarn.

Mesh fabrics are usually made from polyester or nylon, but can also contain copper and stainless steel. Some mesh fabrics are certified to be 100 percent recycled. A mesh fabric is also called a net or tulle. Mesh fabrics are used for a variety of net products, such as fishing nets, hammocks, and net bags. The edges of mesh fabrics can be finished with ribbons, topstitches, and dual-fold bias tape. They can also be stabilized with sheer tricot tape or clear elastic material.

The lifespan of mesh fabric depends on the material, the quality of the fiber, and how it is treated. The most common type of mesh fabric is made from polyester. Although polyester is generally more breathable than nylon, nylon has a little more stretch. A mesh fabric based on nylon feels silkier and feels longer lasting than polyester.